what are you looking for?

Laser crystals play a critical role in the development of modern laser technologies, serving as the essential medium through which laser light is generated and amplified. These specially designed crystals are integral in a wide range of applications, from scientific research to industrial manufacturing. In this article, we will delve into how laser crystals work, their various types, and their critical role in producing coherent light, as well as explore the science behind their operation in both solid-state and nonlinear laser systems.

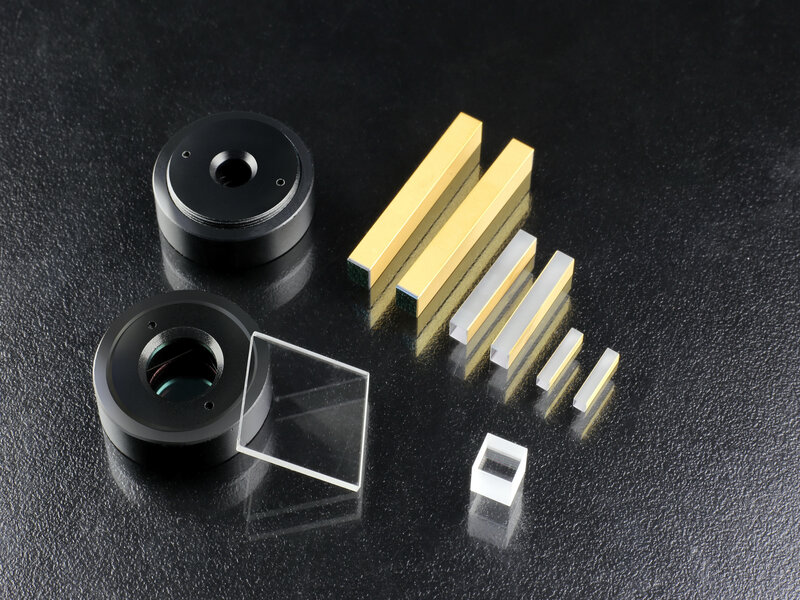

Laser crystals are a type of optical crystal that provides the active medium necessary for the amplification of light in solid-state lasers. They are typically doped with specific ions that enable them to emit light when excited by an external energy source, such as a flash lamp or diode laser. Laser crystals serve as the core component in solid-state lasers, which are one of the most common types of lasers used today.

The principle of laser operation relies on the process of "stimulated emission," first described by Albert Einstein. In a laser crystal, energy is introduced to the system, causing electrons in the crystal’s atoms to jump to a higher energy level. As the electrons return to their ground state, they emit photons (light particles), and this emission stimulates further photon emission in a chain reaction. This results in the amplification of light, leading to the generation of a laser beam.

There are several types of laser crystals, each with unique properties that make them suitable for specific applications. Here are a few of the most common types:

YAG Crystals (Yttrium Aluminum Garnet): YAG crystals, particularly Nd (neodymium-doped YAG), are widely used in industrial and medical lasers. These laser crystals operate at wavelengths of 1064 nm and are highly efficient in converting energy into laser light.

Ti Crystals: Titanium-doped sapphire (Ti ) crystals are known for their tunable laser range, which covers a broad spectrum from 650 nm to 1100 nm. Ti lasers are frequently used in research environments for femtosecond pulse generation.

YVO4 Crystals (Yttrium Orthovanadate): YVO4-based crystals are ideal for producing visible and near-infrared lasers, with applications in telecommunications and precision instrumentation.

LBO (Lithium Triborate) and BBO (Beta Barium Borate) Crystals: These nonlinear crystals are essential in frequency conversion processes, such as second-harmonic generation (SHG), which doubles the frequency of the incoming laser light. LBO and BBO crystals are critical for creating high-power UV and visible lasers.

At the heart of any laser system, the laser crystal serves as the gain medium, a material that can amplify light through the process of stimulated emission. Here's a step-by-step breakdown of how laser crystals function:

Energy Absorption: First, the laser crystal absorbs energy from an external source, known as the pump source. This pump source could be a flash lamp or a diode laser. The absorbed energy excites the atoms within the crystal, raising their electrons to a higher energy state.

Population Inversion: To achieve lasing action, a condition known as population inversion must be met. This means that more electrons are in the excited state than in the lower energy state. In a laser crystal, this is achieved by continuous pumping of energy, creating the conditions necessary for the stimulated emission process to dominate.

Stimulated Emission: As the excited electrons return to their ground state, they release photons. These emitted photons stimulate other excited electrons to release more photons of the same wavelength and phase, resulting in a cascading effect. The emitted light is amplified as it passes through the laser crystal.

Optical Resonator: The laser cavity, formed by two mirrors placed on either side of the crystal, ensures that light bounces back and forth within the crystal. This further amplifies the light, increasing its intensity until it reaches the threshold needed to emit a coherent laser beam.

Laser Emission: Once the light is amplified sufficiently, it passes through one of the partially transparent mirrors, producing the laser beam. The wavelength of the emitted laser light is determined by the type of dopant in the laser crystal.

Nonlinear crystals, such as LBO and BBO, are commonly used in laser systems to modify the frequency of the generated laser light. These crystals exhibit nonlinear optical properties, meaning that the output light from the crystal is not simply a reflection of the input light.

One of the most well-known processes in nonlinear optics is second-harmonic generation (SHG), where a laser crystal takes incoming light and doubles its frequency. This technique is widely used to produce green and blue laser light from infrared sources. For instance, a 1064 nm laser generated by an Nd

Another process is optical parametric amplification (OPA), which is used to generate tunable laser frequencies by combining two wavelengths of light in a nonlinear crystal.

Laser crystals have found applications across a broad spectrum of industries and scientific fields. Here are some of the key uses:

Medical Lasers: Nd lasers are widely used in surgical procedures, including ophthalmology and dermatology. They are also essential in cosmetic treatments, such as tattoo removal and laser hair removal.

Telecommunications: YVO4 crystals are used in telecommunications systems to produce high-power lasers that transmit data over optical fibers.

Defense and Aerospace: Laser rangefinding and targeting systems often rely on erbium-doped glass lasers due to their eye-safe properties.

Several factors can impact the performance and efficiency of laser crystals, including:

Crystal Purity: Impurities within the crystal can affect its ability to amplify light. High-purity crystals are necessary for optimal laser performance.

Doping Levels: The concentration of dopant ions in the crystal must be carefully controlled. Too much or too little doping can affect the efficiency of the laser.

Thermal Management: Lasers generate heat during operation, and this heat can affect the crystal’s performance. Effective cooling systems are essential for maintaining consistent operation.

Coating and Polishing: The surface quality of the crystal affects how well it interacts with the laser cavity. Precision polishing and anti-reflective coatings are crucial to minimize losses.